A Laser Range Scanner Designed for Minimum Calibration Complexity

Abstract

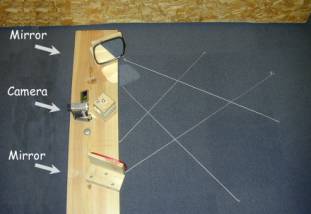

Laser range scanners are a popular method for acquiring three-dimensional geometry due to their accuracy and robustness. Maximizing scanner accuracy while minimizing engineering costs is a key challenge to future scanner designs. Engineering costs arise from both expensive components and difficult calibration requirements. We propose a new range scanner design, specifically chosen to minimize calibration complexity and cost. This design eliminates all actuated components from the calibrated geometry. Since it is difficult to ensure absolute repeatability of moving parts, a design with only statically arranged components can dramatically reduce the costs associated with calibration.

| 3DIM 2001 Paper | [PDF 3.1MB] |

| [PS 4.6MB] | |

| 3DIM 2001 Presentation | [Powerpoint 5.3MB] |

| [PDF 2.4MB] | |

| [HTML] |

Selected Figures

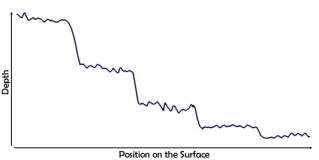

A cross-section of recovered geometry on a target with known steps ranging in depth from 4mm to 1mm.

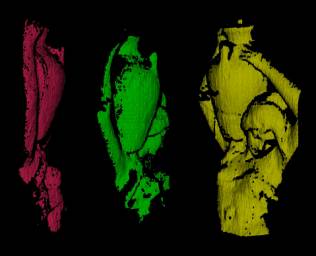

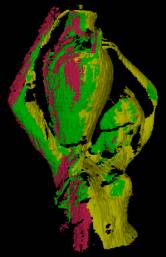

Left: Three meshes scanned from different viewpoints using our scanner. Right: The meshes have been aligned into a single coordinate system.

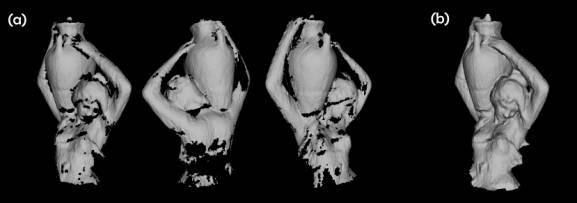

(a) A volumetric method was used to merge twenty-two scans into a single mesh. The single mesh is shown from three viewpoints. (b) A hole filling technique was used to fill holes remaining in areas not observed in the scanning process.